3D Printing

Getting Started

What is 3D printing?

3D printing is a process of creating three-dimensional objects by laying down successive layers of material. Unlike traditional printers that print on paper, 3D printers use a fast-drying and hardening material that is extruded from a nozzle. The material is then built up layer by layer, creating a 3D object.

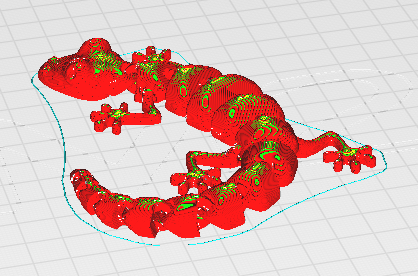

The 3D printing process starts with a digital design of the object that is created using 3D modeling software. This design is then sliced into layers using a slicing software, commonly referred to as a “splicer.” The splicer converts the 3D model into a set of instructions, called G-code, that the 3D printer uses to build the object. The G-code is then sent to the 3D printer, which reads the instructions and starts the printing process. The end result is a three-dimensional object that is an close replica of the digital design.

Printing/Splicing Software

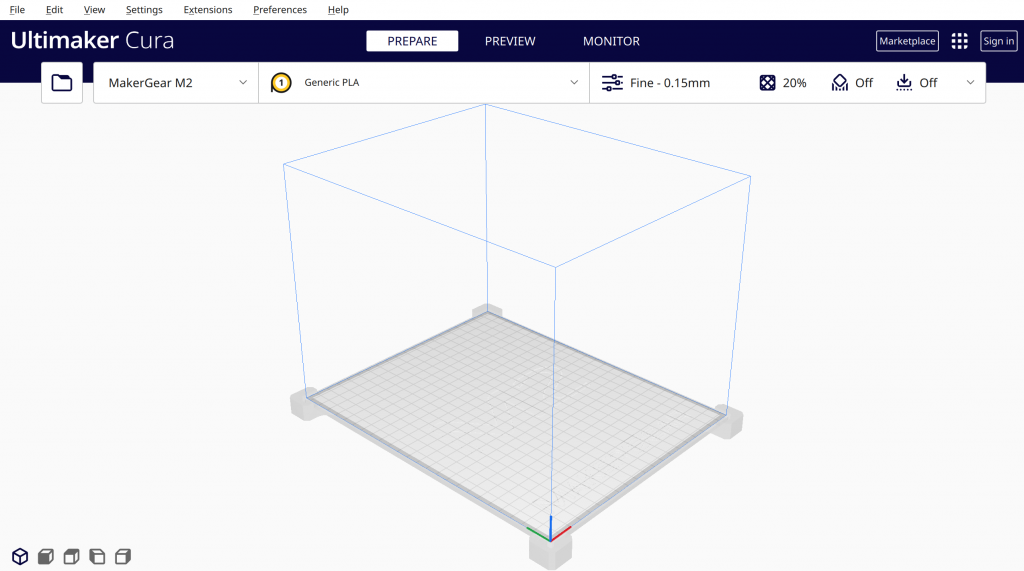

Both the lulzbot and Makergear printers use a version of Cura. Cura is a common splicer software which allows you to control difference parameters such as speed , temperature, and material flow. With Cura, you can also preview and adjust the layout of your model before starting the print, helping to avoid potential issues and resulting in higher quality prints. The software is user-friendly and allows you to quickly and easily slice your 3D models into printable layers. Cura offers a range of customizable settings and advanced features that can help you achieve your desired results.

Printing

There are a few things to consider while printing on a 3d printer. Unlike 2d printers, these printers use filament made from different types of plastic. These plastics had different cooling and melting temperatures, affecting how you want to print. For example, A slow melting temperature plastic might burn if the nozzle or the bed temperature is too high.

Cura has built-in commonly used plastics and their relative temperatures.

Things to look out for

- Nozzle Temperature

- Bed Temperature

- Printing speed

- Print dimensions

- Support material

Support material helps the printer print things like overhangs and parts of the print that aren’t attached to the bed. Its also used to stop the print from warping on the heated bed.

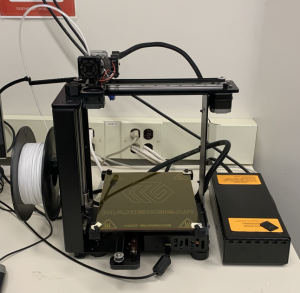

Printing in the hackerspace

All the printers can only be accessed through the hackerspace network. Make sure to use one of the computers in hackerspace.

Setting up cura

If your not able to print from cura, please inform one of the iLabs or Lab Techs to reconnect cura.

Lulzbot

https://lulzbot-octo.cs.rutgers.edu

Nozzle: 0.4mm

Print Area: 152 mm x 152 mm x 158 mm

Top Print Speed: 275mm/sec

When using the lulzbot, find the lulzbot cura on the pcs. It should be a green icon with a C in it

MakerGear

https://makergear-octo.cs.rutgers.edu

Nozzle: 0.4mm

Print Area: 200 mm x 250 mm x 200 mm

Top Print Speed: 450 mm/sec

When using the maker gear, find the ultimate cura on the pcs. It should be a blue icon

Post Printing / Maintenance

Cleaning Up Prints

When retrieving your print from the printer bed, it is important to take precautions to prevent any damage to the bed. Some prints may be stuck, which can create issues when trying to remove them. To avoid any potential problems, please take your time when removing your print, being careful not to scratch the bed or cause any other damage. By doing so, you can help to ensure that the printer remains in good condition and continues to produce high-quality prints. Thank you for your attention to this important matter.

Cleaning up

To help maintain a clean and organized workspace, please dispose of any excess support material in the designated recycling bin. Additionally, if you notice that the printer has run out of filament during your printing job, please inform one of the iLabs or Lab Technicians for assistance. By following these guidelines, you can help to ensure that our equipment remains in good condition and that others can use the printer with ease.